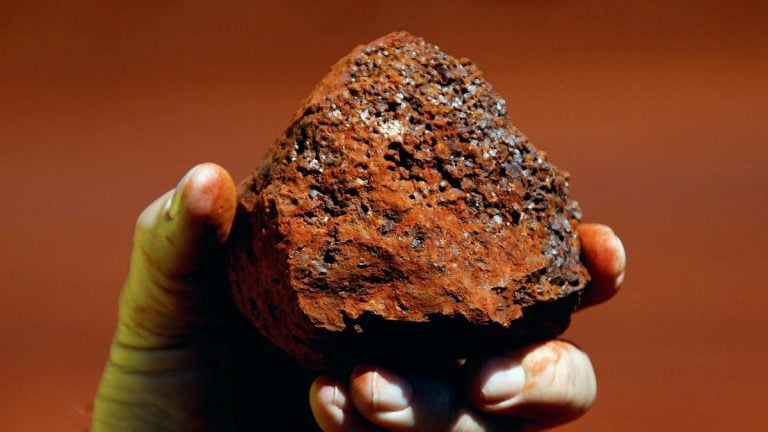

Copper ore is a compound of minerals in which copper is present in sufficient concentration for its further processing and use for industrial purposes.

In production, it is advisable to use enriched ore with a metal content of at least 0.5-1%.

Characteristic properties: corrosion resistance, high thermal and electrical conductivity.

At the same time, the element has high antibacterial properties and destroys influenza viruses and staphylococci.

In the industrial complex, copper is most often used in alloys with other components: nickel, zinc, tin, gold, etc.

Application of copper ore

Due to its low resistivity, copper is actively used in the electrical field for the manufacture of power cables and wires. Good thermal conductivity allows this metal to be used in cooling radiators and air conditioners.

The following manufacturing sectors cannot do without copper:

- mechanical engineering (window lifters, bearings);

- shipbuilding (plating of hulls and structures);

- construction (pipes, roofing and facing materials, plumbing equipment, etc.).

For the jewelry industry, alloys with gold are relevant, which increase mechanical strength and abrasion resistance.

Experts predict large-scale use of metal as antibacterial surfaces in medical institutions (railings, doors, handles, handrails, etc.).

Groups of copper ores

All copper ores are usually divided into nine industrial-geological types, which in turn are divided into six groups according to origin:

Stratiform group

This group includes copper shales and sandstones. These materials are represented by large deposits. Their characteristic features are: simple sheet form, uniform distribution of useful components, flat surface bedding, allowing the use of open mining methods.

Pyrite group

This includes native copper, vein and copper-pyrite compounds. The native metal is most often found in the oxidation zones of copper sulfide mines, along with other oxidized minerals.

Copper pyrite metals differ in shapes and sizes. The main mineral in the ore is pyrite; chalcopyrites and sphalerites are also present.

Vein ores are characterized by a vein structure with inclusions. Such ores, as a rule, occur in contact with porphyries.

Porphyry copper (hydrothermal)

These deposits, together with copper and molybdenum, contain gold, silver, selenium and other useful elements, the presence of which is significantly higher than normal.

Copper-nickel

The deposits are presented in sheet, lens-shaped, irregular and vein forms. The metal has a massive texture interspersed with cobalt, platinum group metals, gold, etc.

Skarn Ore

Skarn ores are local deposits in limestones and calcareous-terrigenous rocks. They are characterized by small sizes and complex morphology. The copper concentration is high, but uneven – up to 3%.

Carbonate

This group includes iron-copper and carbonatite ore. So far, the only deposit of this type of copper has been discovered in South Africa. This complex mine belongs to the alkaline rock massif.

What ores are copper obtained from

There are almost 250 types of copper, but only 20 types are used in industry. The most common of them:

Chalcocite

A compound of minerals containing sulfur (20%) and copper (80%). It is called “copper luster” because of its characteristic metallic luster. The ore has a dense or granular structure of black or gray hue.

Chalcopyrite

The metal is of hydrothermal origin and is found in skarns and greisens. Most often it is part of polymetallic ore along with galena and sphalerite.

Bornite

A common mineral of the sulfide class in nature, one of the main elements of copper ores. It has a characteristic bluish-purple tint. Contains copper (63.33%), iron (11.12%), sulfur (25.55%) and silver impurities. It occurs in the form of dense, fine-grained masses.

Methods of mining copper ore

Depending on the depth of the mine, open and closed methods of metal extraction are used.

In closed (underground) mining, mines are built several kilometers long. The mines are equipped with elevators to move workers and equipment, as well as to transport minerals to the surface.

Underground, the rock must be crushed using special drilling equipment with spikes. Then, with the help of buckets, the ore is collected and loaded.

The open method is relevant when the deposits are located at a depth of 400-500 meters. First, the top layer of waste rock is removed, after which the copper ore is removed. To make it easier to get hard rocks, it is first destroyed with explosive devices.

Technological process of copper production

There are two main methods for producing copper:

- pyrometallurgical;

- hydrometallurgical.

The first method involves fire refining of metal and allows you to process any raw material with the extraction of all useful elements. Using this technology, it is possible to obtain copper even from poor rock, in which the metal content is below 0.5%. The second method is used, as a rule, only for processing oxidized or native ore with a low copper content.

Mining of copper ores in the world

Copper mines are not concentrated in specific geographical areas, but are found in different countries. In America, chalcocite deposits are being developed in the states of Nevada and Arizona. Deposits of copper oxide – cuprite – are common in Cuba. Copper chloride is mined in Peru.

There are almost no sources of enriched ores left in the world; copper has been mined for several hundred years, so all the rich mines have long been developed. In industry it is necessary to use low-grade minerals (up to 0.5% copper).

The list of countries rich in copper ores includes: Chile, America, China, Kazakhstan, Poland, Indonesia, Zambia. The Russian Federation’s share in world ore production is 9% (this is third place after Chile and the USA). Chile is the leader in mineral reserves, containing 33% of the world’s copper.

The largest mines are:

Chukicamata mine (Chile)

Development has been going on for more than 100 years; during this period, 26 million tons of metal were developed.

Escondida mine (Chile). Mining has been carried out since 1990;

Grasberg Mine (Indonesia).

Recently, large mines were discovered in Peru (Antamina), Brazil (Salobu), and Kazakhstan (Nurkazgan).

Experts say that the volume of economically viable copper is more than 400 million tons. Worldwide.

Copper ore mining in Russia

The structure of the copper raw material base in Russia differs significantly from the world market. The main share in it falls on sulfide copper-nickel (40%) and pyrite (19%) mines. While in other countries porphyry copper deposits and cuprous sandstones predominate.

Copper ore deposits in Russia

Answering the question of where copper ores are mined in Russia, the Taimyr Autonomous Okrug should first be highlighted. More than 60% of all copper ore deposits in Russia are concentrated in the Oktyabrsky, Tapakhninsky and Norilsk deposits. About one third of the mineral is mined in the Ural copper mining region.

A large Udokan mine has been discovered in the Chita region, which has not yet been developed due to undeveloped transport infrastructure. According to expert data, the exploited deposits in the Russian Federation will last no more than 30 years.