Ore is the main raw material for the global metallurgical industry.

The economies of different countries largely depend on the market for this mineral, which is why the development of mines is receiving increased attention all over the world.

Ores are rocks that are used for processing and extracting the metals they contain. The types of these minerals differ in origin, chemical content, concentration of metals and impurities. The chemical composition of the ore contains various oxides, hydroxides and carbon dioxide salts of iron.

Ore properties

Iron is a common chemical element in nature. Its content in the earth’s crust is about 4.2%. But in its pure form it is almost never found, most often in the form of compounds – in oxides, iron carbonates, salts, etc.

Iron ore is a combination of minerals with a significant amount of iron. In the national economy, the use of ores containing more than 55% of this element is considered economically feasible.

What is made from ore

The iron ore industry is a metallurgical industry that specializes in the extraction and processing of iron ore. The main purpose of this material today is the production of cast iron and steel.

All products made from iron can be divided into groups:

- Pig iron with high carbon concentration (above 2%).

- Cast iron.

- Steel ingots for the production of rolled products, reinforced concrete and steel pipes.

- Ferroalloys for steelmaking.

What is ore needed

The material is used for smelting iron and steel. Today there is practically no industrial sector that can do without these materials.

Cast iron is an alloy of carbon and iron with manganese, sulfur, silicon and phosphorus. Pig iron is produced in blast furnaces, where the ore is separated from iron oxides at high temperatures. Almost 90% of the resulting cast iron is marginal and is used in steel smelting.

Various technologies are used:

- electron beam melting to obtain pure high-quality material;

- vacuum treatment;

- electro-slag remelting;

- steel refining (removal of harmful impurities).

The difference between steel and cast iron is the minimum concentration of impurities. Oxidative smelting in open-hearth furnaces is used for purification.

The highest quality steel is smelted in electric induction furnaces at extremely high temperatures.

What types of ores are there

Ore differs in the concentration of the element it contains. It can be enriched (with a concentration of 55%) and poor (from 26%). It is advisable to use low-grade ores in production only after enrichment.

Based on their origin, the following types of ores are distinguished:

- Magmatogenic (endogenous) – formed under the influence of high temperature;

- Superficial – settled remains of the element on the bottom of sea basins;

- Metamorphogenic – obtained under the influence of extremely high pressure.

Main mineral compounds containing iron:

- Hematite (red iron ore). The most valuable source of iron with an element content of 70% and with a minimum concentration of harmful impurities.

- Magnetite. A chemical element with a metal content of 72% has high magnetic properties and is mined from magnetic iron ores.

- Siderite (iron carbonate). There is a high content of waste rock, the iron itself is about 45-48%.

- Brown iron ores. A group of aqueous oxides with a low percentage of iron, with admixtures of manganese and phosphorus. An element with such properties is characterized by good restoreability and a porous structure.

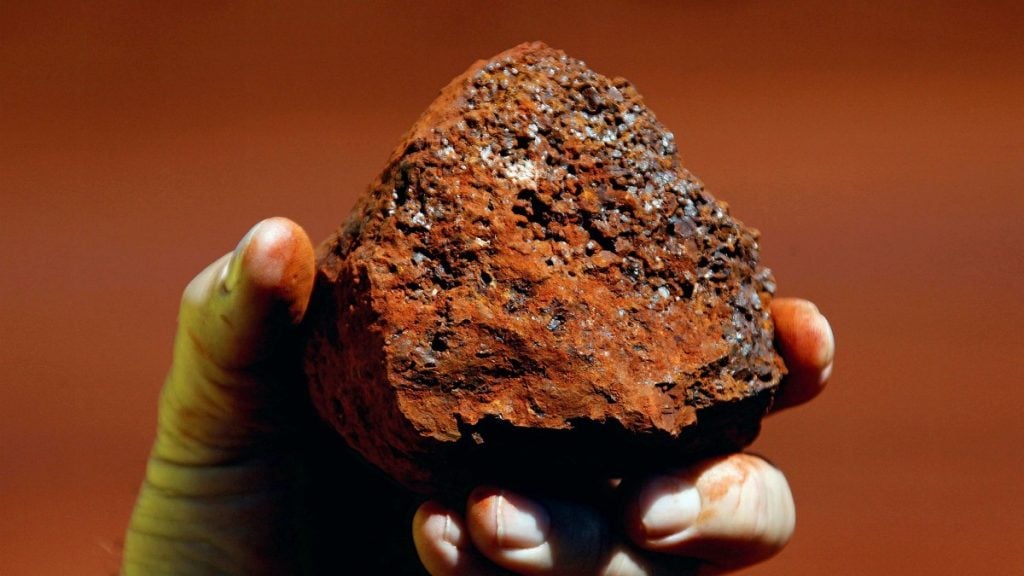

What does ore look like

The type of material depends on its composition and the content of additional impurities. The most common red iron ore with a high percentage of iron can be found in different states – from very dense to dusty.

Brown iron ores have a loose, slightly porous structure of brown or yellowish color. Such an element often requires enrichment, but is easily processed into ore (high-quality cast iron is obtained from it).

Magnetic iron ores are dense and granular in structure, looking like crystals embedded in the rock. The color of the ore is characteristic black-blue.

How ore is mined

Iron ore mining is a complex technical process that involves diving into the bowels of the earth to search for minerals. Today, there are two methods of ore mining: open and closed.

Ore mining by open pit method

Open (quarry method) is a common and safest option compared to closed technology. The method is relevant for cases where there are no hard rocks in the working area, and there are no populated areas or utility systems nearby.

First, a quarry up to 350 meters deep is dug, after which iron is collected and removed from the bottom by large machines. After extraction, the material is sent on diesel locomotives to steel and iron factories.

Quarries are dug using excavators, but this process takes a lot of time. As soon as the machine reaches the first layer of the mine, the material is submitted for examination to determine the percentage of iron content and the feasibility of further work (if the percentage is above 55%, work in this area continues).

Closed mining method

Mine (closed) ore mining is used only if it is planned to maintain the integrity of the landscape in the area where ore deposits are being mined.

This method is also relevant for work in mountainous areas. In this case, a network of tunnels is created underground, which leads to additional costs – the construction of the mine itself and the complex transportation of metal to the surface. The main drawback is the high risk to the lives of workers; the mine can collapse and block access to the surface.

Countries rich in ores

Iron ore mining is one of the leading areas of the economic complex of the Russian Federation. But despite this, Russia’s share in world ore production is only 5.6%. World reserves amount to about 160 billion tons. The volume of pure iron reaches 80 billion tons.

The distribution of minerals by country is as follows:

- Russia – 18%;

- Brazil – 18%;

- Australia – 13%;

- Ukraine – 11%;

- China – 9%;

- Canada – 8%;

- USA – 7%;

- other countries – 15%.

Significant deposits of iron ore have been noted in Sweden (the cities of Falun and Gellivar). In America, a large amount of ore was discovered in the state of Pennsylvania. In Norway, the metal is mined in Persberg and Arendali.

The Kursk magnetic anomaly is a large deposit of iron ore in the Russian Federation and in the world, in which the volume of unrefined metal reaches 30,000 million tons.

Kursk Magnetic Anomaly

The area of the Kola Peninsula mines is 115,000 sq. km. Iron, nickel, copper ores, cobalt and apatites are mined here.

The Ural Mountains are also among the largest ore deposits in the Russian Federation. The main development area is Kachkanar. The volume of ore minerals is 7000 million tons.

The metal is mined in smaller quantities in the West Siberian basin, Khakassia, the Kerch basin, Zabaikalsk and the Irkutsk region.